Compact freeze-drying equipment

Making freeze-dried products more accessible. Here is a guide to products that fulfill that desire.

How about a compact type of small freeze-drying (vacuum freeze-drying) machine that is affordable in price and size?

With casters, it is easy to set up and move.

Want to make your own freeze-dried products?

It can be used for a variety of purposes, such as long-term storage of fruits and vegetables, selling original menus at restaurants, and making pet treats.

What is freeze-drying (vacuum freeze-drying)?

Freeze drying (vacuum freeze drying) is a technique for drying food and other raw materials.

In this technology, the raw materials are first frozen, then placed in a vacuum environment and heated to remove water from the materials as the ice sublimates.

The resulting dried product is widely used in the food industry for soups, desserts, etc., as it has a much longer shelf life at room temperature and retains its flavor and nutritional value.

.png)

Basic Functions of Compact Freeze Drying Equipment

Small freeze-drying machines are designed for homes and small businesses, and are compact yet high-performance.

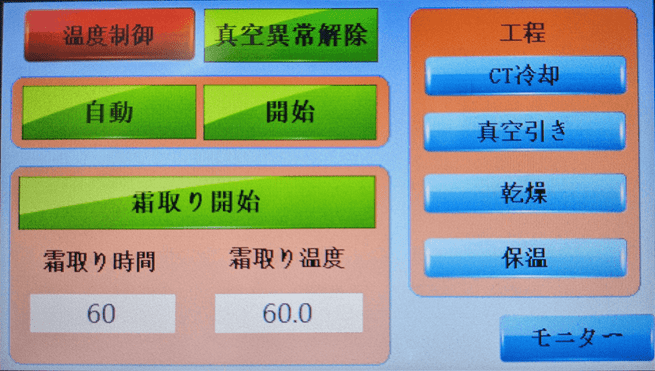

It is equipped with a “vacuum drying function” that sublimates moisture under vacuum conditions.

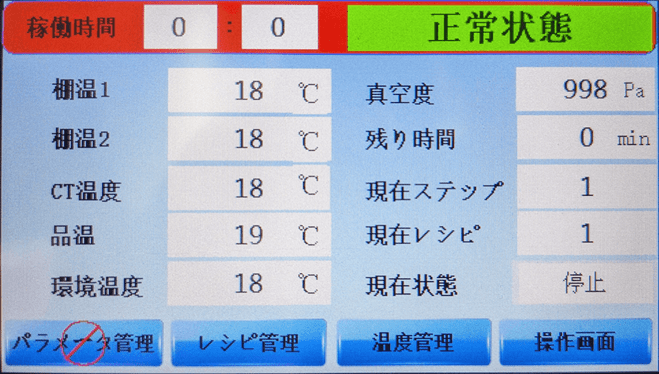

In addition, the “automatic control function” that can automatically manage temperature and vacuum makes operation easy even for beginners.

And, the space-saving design and energy efficiency of the machine enables high-quality freeze-drying with low running costs, even over long periods of use.

Our freeze-drying equipment has a touch panel with Japanese-language support, so operation is worry-free.

If you have any concerns about the introduction of the system, we can provide extensive support, as we have also delivered large production machines for factories.

|

|

Operation screen (example)

Product List※1,850,000 yen (excluding tax) ~ We will deliver by car

|

Freeze drying (vacuum freeze drying) equipment TFDS-1 Standard specifications (with external oil-sealed rotary vacuum pump) Drying Capacity:1-2kg Size:W545mm×D745mm×H820mm Weight:53kg Color:Black/White Price:1,850,000 yen (excluding tax) |

.png) |

Freeze drying (vacuum freeze drying) equipment TFDS-4 Standard specifications (with external oil-sealed rotary vacuum pump) Drying Capacity:4-5kg Size:W560mm×D785mm×H820mm Weight:87kg Color:Black/White Price:2,200,000 yen (excluding tax) |

.png) |

Freeze drying (vacuum freeze drying) equipment TFDS-6 Standard specifications (with external oil-sealed rotary vacuum pump) Drying Capacity:6-8kg Size:W770mm×D810mm×H1190mm Weight:132kg Coloer:Black/White Price:2,850,000 yen (excluding tax) |

.png) |

Freeze drying (vacuum freeze drying) equipment TFDS-10 Standard specifications (with external oil-sealed rotary vacuum pump) Drying Capacity:10-13kg Size:W720mm×D1150mm×H1190mm Weight:145kg Color:Black/White Price:3,650,000 yen (excluding tax) |

Advantages and disadvantages of freeze-drying

Advantages of Freeze Drying

・Less loss of nutritional value and flavor of food due to drying

・Lightweight and easy to carry

・Long-term preservation is possible

Disadvantages of freeze-drying

・High capital and energy costs

・Takes time to dry

・Easily oxidizes and absorbs moisture when exposed to air

What you need to make freeze-dried products

・Freezing equipment (freezers):

-20°C or lower freezer recommended (depends on material)

・Vacuum Freeze Drying Equipment:

The main unit of the device for sublimating water in a frozen state.

・Vacuum pump:

A device used to create a vacuum (our product comes as a set with the main unit)

・Material (raw material):

Choosing quality materials has a big impact on the finished product

・packing material (boxes, insulation, shock resistance, etc.):

Freeze-dried products are susceptible to moisture absorption and should be packaged in a sealed package with a desiccant.

Freeze-drying production process (e.g. fruits)

1.Pretreatment:Clean the material and cut it to the appropriate size

2.freeze:After pre-processing, the material is frozen in a freezer.

3.Primary Drying:Low-temperature heating in a vacuum environment sublimates frozen moisture.

This process allows water to evaporate as ice and dries the material

4.Secondary drying:The water remaining inside the cells of the material is further removed at a low temperature.

This process controls the final moisture content

5.Packaging and Storage:Seals product completely dry and preserves

Sealing with desiccant, oxygen absorber, etc. will preserve the product for an even longer period of time.

>>Freeze-dried production process

FAQ

Q. What can a freeze-drying machine do?

A. Various products can be made, such as freeze-dried fruits, freeze-dried miso soup and cup noodle ingredients, and pet treats.

Q. What is the turnaround time for small freeze-drying equipment?

A. Estimated delivery time is 1-3 months after ordering.

Q. Do you charge for shipping?

A. Hokkaido, Okinawa, and remote islands will incur shipping charges, but for other areas, shipping charges are included in the product price.

Purchase Information

For questions about our products or to make a purchase, please contact us at

Business Hours:weekday9:00~17:00

TOYO-GIKEN CO.,LTD.

3-754-11,NONOSHITA,NAGAREYAMA-SHI CHIBA,JAPAN

(TEL)04-7145-1040

<Dedicated mail address for small freeze-drying equipment>

.png)